SANYO DENKI Stepper motor

SANYO DENKI Stepper motor Specification

- Protection Class

- Class B Insulation

- Protection Level

- IP50

- Components

- Rotor, Stator, Bearings, Shaft, Lead Wires

- Rated Insulation Voltage

- 500 V AC for 1 minute

- Operating Voltage

- 24 V DC (typical drive supply)

- Rated Operation Voltage

- 2.8 V

- Thickness

- 68 mm (Frame size: 86mm or NEMA 34)

- Features

- High Torque, Low Noise, Precision Step Angle, Reliable Performance

- Rated Current

- 2.8 A/Phase

- Base Material

- Steel

- Cover Material

- Aluminum Alloy

- Control System

- Microstepping Driver Compatible

- Current Rating

- 2.8 A

- Material

- High Grade Metal

- Surface Finish

- Anodized & Painted

- Standard

- IEC / JIS (Japanese Industrial Standards)

- Surface Color

- Black & Silver

- Rated Voltage

- 2.8 V

- Maximum Output Current

- 2.8 A/Phase

- Dimension (L*W*H)

- 86 mm x 86 mm x 68 mm

- Application

- Industrial Automation, CNC Machines, Robotics

- IP Rating

- IP50

About SANYO DENKI Stepper motor

Sanyo Denki Japan Make Stepper motors

Bipolar Stepper motor ( 1 Nm to 22 Nm Torque )

High Torque density

High Power Rare earth Magnets

Rugged Design and long life Bearing

Low vibration , High Speed , High Torque

4 Lead / 8 Lead , Series / Parallel , Hybrid Stepper motors

Frame Size :: 28 mm to 110 mm

Capacity :: 10 Kgcm to 220 Kgcm

Current :: 1A to 6A

RPM :: Load Dependent Can go max upto 500 rpm

Optional Accessories

Motion Controllers , PLC , Display HMI Stepper Drivers , Servo motor + Drivers , Control panels etc

Precision and Power for Industrial Applications

Combining high torque output with a precise 1.8 step angle, this SANYO DENKI stepper motor is ideal for applications where accuracy and strength are crucial. Its robust specification meets IEC/JIS standards, making it suitable for a range of demanding settings, such as industrial automation and CNC machining.

Reliable Construction and Advanced Protection

Manufactured with high-grade metal and finished in anodized black and silver, this motor features a steel base and aluminum alloy cover for maximum durability. Rated at IP50 and with Class B insulation, it is designed to withstand the rigors of continuous industrial use while maintaining safe operation.

FAQs of SANYO DENKI Stepper motor:

Q: How is the SANYO DENKI Stepper Motor typically used in industrial environments?

A: This stepper motor is commonly utilized in industrial automation systems, CNC machines, and robotics where precise positioning and high torque are required. Its reliable performance and compatibility with microstepping drivers make it well-suited for tasks demanding accurate control and robust movement.Q: What are the benefits of the 1.8 step angle and high holding torque in this stepper motor?

A: The 1.8 step angle allows for precise incremental movement, granting finer positional control important for detailed machining or automation tasks. The high 7.2 Nm holding torque ensures the motor can securely maintain or move loads even in challenging conditions.Q: When is it necessary to utilize the IP50 protection level in motor applications?

A: IP50 protection offers limited dust ingress protection, making this motor suitable for environments where dust is present but liquid exposure is minimal. Applications that involve moderate industrial settings, away from water or heavy contamination, would benefit most from this protection rating.Q: Where should the SANYO DENKI Stepper Motor be installed for optimal performance?

A: For optimal performance and longevity, install the motor in environments conforming to its IP50 rating and within the electrical specifications provided (2.8 A/phase, 2.8 V, typical drive supply of 24 V DC). Secure mounting on compatible machinery and ensuring adequate ventilation are also recommended.Q: What process is recommended for wiring and powering this stepper motor?

A: Connect the motors lead wires (500 mm length) to a compatible microstepping driver, ensuring proper polarity and secure connections. Supply the driver with 24 V DC (typical) and set the output current to match the 2.8 A/phase rating of the motor. Always follow IEC/JIS safety standards during installation.Q: How does the motors design enhance its reliability and lifespan?

A: With high-grade metal construction, anodized and painted surfaces, and durable steel and aluminum alloy components, the motor is built for longevity and resistance against wear. Combined with robust insulation and dielectric strength, these features help maintain reliable operation over extended periods in industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stepper motors Category

Motion King Stepper 34HS9301

Product Type : Other, Stepper Motor

Features : High Torque Low Vibration

Application : Industrial Automation

Control System : Stepper Motor Driver

Components : Rotor Stator Bearings

Connectivity Type : Wiring

SY85-STH SOYO Stepper motors

Product Type : Other, Stepper motor

Features : Precision control reliable performance

Application : Industrial automation

Control System : Electrical control system

Components : Stepper motor

Connectivity Type : Wired

Soyo Stepping SY57STH56-1006A

Product Type : Stepper Motor, Other

Features : High Precision Durable

Application : Stepper Motor Applications

Control System : Stepbased control

Components : Rotor Stator Shaft

Connectivity Type : Electrical

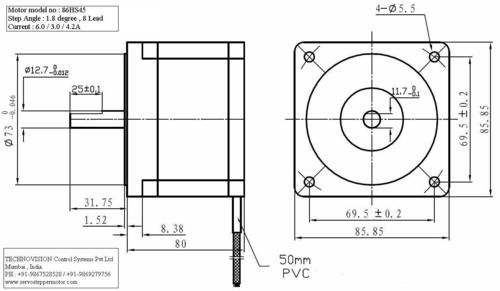

86HS45 Leadshine Stepper Motor 45Kgcm

Product Type : Stepper Motor, Other

Features : High torque compact size reliable

Application : Stepper motor for precision control

Control System : Closedloop stepper control

Components : Motor body and shaft

Connectivity Type : Wired connection PVC cable

GST : 27AADCT3013C1ZX

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS